Well-designed Used Chinese Brand Combine Harvester for Rice Wheat

Having a sound small business credit score, outstanding after-sales services and modern manufacturing facilities, we’ve got earned an fantastic reputation among our buyers across the globe for Well-designed Used Chinese Brand Combine Harvester for Rice Wheat, We believe that in high-quality in excess of quantity. Before export in the hair there is strict quality control check during treatment as per international top quality standards.

Having a sound small business credit score, outstanding after-sales services and modern manufacturing facilities, we’ve got earned an fantastic reputation among our buyers across the globe for China Agricultural Machinery, Machine, We’ve got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any complete acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Features and Advantages

1.Gookma GH110 half feeding combine rice harvester is a national major support project of agricultural machinery.

2.It’s convenient in operating, it may be operated by both male and female easily. It’s small in size, light in weight, easy in travel control, flexible in turning. It’s simple in disassembling and convenient for maintenance.

3.With high adaptability, it can be operated in both dry fields and paddy fields, and is suitable for harvesting in the large fields in plain areas and in the small fields in hill areas.

4.It’s strong in power and grade ability, it can pass the ridges conveniently and flexibly.

5.It’s of compact structure, threshes in two times. The first threshing integrates threshing and conveying, and the second threshing integrates threshing and sundries removal. The overall threshing effect is good.

6.Mini half-feeding is the current advanced harvesting technology in the world. It’s of high harvesting efficiency and low fuel consumption, and ensures the recycling of straws easily and conveniently.

Applications

Gookma small half feeding combine rice harvester is suitable for both family use and for small business purpose, it has been selling well and very popular in both domestic and overseas market, and has been enjoying high reputation among customers.

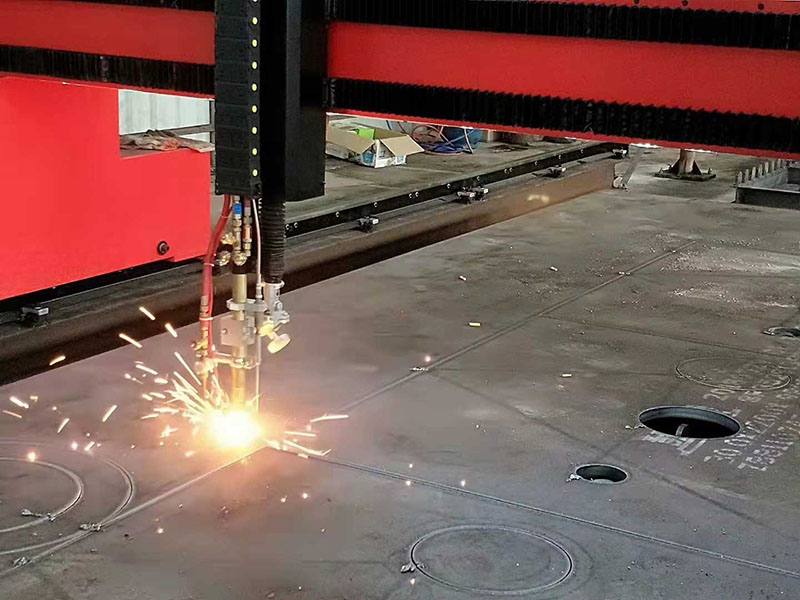

Production Line

Production Video

Well-designed China Agricultural Machinery, Machine, We’ve got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any complete acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Video

1.Gookma GH110 combine rice harvester is a half feeding rice harvester, and is a national major support project of agricultural machinery.

2.It’s convenient in operating, it may be operated by both male and female easily. It’s small in size, light in weight, easy in travel control, flexible in turning. It’s simple in disassembling and convenient for maintenance.

3.With high adaptability , it can be operated in both dry fields and water fields, and is suitable for harvesting in the large fields in plain areas and in the small fields in hill areas.

4.It’s strong in power and grade ability, it can pass the ridges conveniently and flexibly.

5.It’s of compact structure, threshes in two times. The first threshing integrates threshing and conveying, and the second threshing integrates threshing and sundries removal. The overall threshing effect is good.

6.Mini half-feeding is the current advanced harvesting technology in the world. It’s of high harvesting efficiency and low fuel consumption, and ensures the recycling of straws easily and conveniently.

| Name | Half-feeding Combine Rice Harvester | |||

| Model | GH110 | |||

| Structure form | Crawler self-propelling | |||

|

Engine |

Model | ZH1110/ZS1110/H20 | ||

| Type | Single-cylinder four-stroke horizontal water-cooled (Condenser cooled engine optional) | |||

| Power | 14.7KW | |||

| Speed | 2200 rpm | |||

| Overall dimension in operating status(L*W*H) | 2590*1330*2010mm (102*52*79in) | |||

| Weight | 950kg (2094lb) | |||

| Width of cutting table | 1100mm (43in) | |||

| Feeding quantity | 1.0kg/s (4.4lb/s) | |||

| Minimum ground clearance | 172mm (6.8in) | |||

| Theoretical operating speed | 1.6-2.8km/h (3250-9200ft/h) | |||

| Mud depth | ≦200mm (7.9in) | |||

| Total loss | ≦2.5% | |||

| Sundries | ≦1% (with wind selection) | |||

| Breakage | ≦0.3% | |||

| Hourly production | 0.08-0.15ha/h | |||

| Fuel consumption | 12-20kg/ha (26-44lb/ha) | |||

| Type of cutter | Reciprocating type | |||

|

Thresher drum |

Quantity | 2 | ||

| Main drum type | Stripping belt | |||

| Main drum dimension (perimeter*width) | 1397*725mm (55*29in) | |||

| Type of concave screen | Grid type | |||

|

Fan |

Type | Centrifugal | ||

| Diameter | 250 | |||

| Quantity | 1 | |||

|

Crawler |

Specification(pitch number*pitch*width) | 32*80*280mm (32*3.2*11in) | ||

| Gauge | 610mm (24in) | |||

| Transmission type | Mechanical | |||

| Brake type | Internal jaw | |||

| Re-thresher type | Axial flow spiked | |||

| Grain collecting type | Manual grain collecting | |||

Video

●Flexible in field operating

● Low-cut stubble

● Strong power

● Low fuel consumption

● High working efficiency

● Wide adaptability for fallen crops

● Keeps straws

|

Name |

Half Feeding Rice Combine Harvester |

|||

|

Model |

GH120 |

|||

|

Sizes (L*W*H) (mm) (in) |

|

3650*1800*1820 (144*71*72) |

||

|

Weight (kg) (lb) |

1480 (3267) |

|||

|

Engine |

Model |

2105 |

||

|

Type |

Vertical water cooling two cylinder four stroke diesel engine |

|||

|

Rated output / speed [ps (KW) / rpm] |

35 (26) / 2400 |

|||

|

Fuel |

Diesel |

|||

|

Starting Mode |

Electrical starting |

|||

|

Walking Section |

Track (pitch number*pitch*width) (mm) (in) |

42*90*350 (42*3.5*13.8) |

||

|

Ground clearance(mm) (in) |

220 (8.7) |

|||

|

Shift mode |

Hydrostatic continuously variable transmission (HST) |

|||

|

Shift grade |

Stepless (subtransmission 2 grade ) |

|||

|

Walking speed |

Forward (m/s) (ft/s) |

low speed: 0-1.06, (0-3.48) high speed: 0-1.51 (0-4.95) |

||

|

Backward (m/s) (ft/s) |

llow speed: 0-1.06, (0-3.48) high speed: 0-1.51 (0-4.95) |

|||

|

Steering mode |

Hydraulic control |

|||

|

Harvesting Section |

Harvesting lines |

3 |

||

|

Harvesting width (mm) (in) |

1200 (47) |

|||

|

Cutting height range (mm) (in) |

50-150 (1.97*5.9) |

|||

|

Adaptable height of crop (full height) (mm) (in) |

650-1200 (25.6*47.3) |

|||

|

Fallen crops adaptability (degrees) |

Cuttingforward direction:≤75° Cutting reverse direction: ≤65° |

|||

|

Threshing depth control system |

Manual |

|||

|

Gear of cutting table |

3 levels (low speed, high speed, middle speed) |

|||

|

Threshing Section |

Threshing system |

Monocular, axial, low detachable |

||

|

Threshing cylinder |

Diameter* length (mm) (in) |

380*665 (15*26.2) |

||

|

Speed (rpm) |

630 |

|||

|

Secondary transmission mode |

Screw auger |

|||

|

Screening method |

Shaking, blasting, sucking |

|||

|

Grain Discharging Section |

Grain Discharging |

Funnel |

||

|

Grain tank |

Capacity [L (bag × 50L) ] |

105 (2×50) |

||

|

Grain unloading port |

2 |

|||

|

Straw Cutting Section |

Factory style |

Straw cutting length (mm)(in) |

65 (2.6) |

|

|

Working Efficiency |

Ha/h |

0.1 – 0.2 |

||

|

Technical parameters are subject to change without prior notice. |

||||