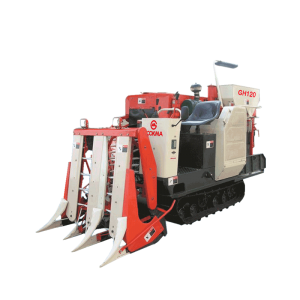

High Quality for Combine Harvester/Rice Harvester/Wheat Harvester/Corn Harvester

Our enterprise insists all along the standard policy of “product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff” as well as consistent purpose of “reputation first, client first” for High Quality for Combine Harvester/Rice Harvester/Wheat Harvester/Corn Harvester, We warmly welcome pals from all walks of everyday living to cooperate with us.

Our enterprise insists all along the standard policy of “product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff” as well as consistent purpose of “reputation first, client first” for China Combine Harvester and Rice Harvester, We follow superior mechanism to process these items that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that permit us to provide unmatched quality of products and solutions for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Specifications

| Name | Half-feeding Combine Rice Harvester | |||

| Model | GH110 | |||

| Structure form | Crawler self-propelling | |||

|

Engine |

Model | ZH1110/ZS1110/H20 | ||

| Type | Single-cylinder four-stroke horizontal water-cooled (Condenser cooled engine optional) | |||

| Power | 14.7KW | |||

| Speed | 2200 rpm | |||

| Overall dimension in operating status(L*W*H) | 2590*1330*2010mm (102*52*79in) | |||

| Weight | 950kg (2094lb) | |||

| Width of cutting table | 1100mm (43in) | |||

| Feeding quantity | 1.0kg/s (4.4lb/s) | |||

| Minimum ground clearance | 172mm (6.8in) | |||

| Theoretical operating speed | 1.6-2.8km/h (3250-9200ft/h) | |||

| Mud depth | ≦200mm (7.9in) | |||

| Total loss | ≦2.5% | |||

| Sundries | ≦1% (with wind selection) | |||

| Breakage | ≦0.3% | |||

| Hourly production | 0.08-0.15ha/h | |||

| Fuel consumption | 12-20kg/ha (26-44lb/ha) | |||

| Type of cutter | Reciprocating type | |||

|

Thresher drum |

Quantity | 2 | ||

| Main drum type | Stripping belt | |||

| Main drum dimension (perimeter*width) | 1397*725mm (55*29in) | |||

| Type of concave screen | Grid type | |||

|

Fan |

Type | Centrifugal | ||

| Diameter | 250 | |||

| Quantity | 1 | |||

|

Crawler |

Specification(pitch number*pitch*width) | 32*80*280mm (32*3.2*11in) | ||

| Gauge | 610mm (24in) | |||

| Transmission type | Mechanical | |||

| Brake type | Internal jaw | |||

| Re-thresher type | Axial flow spiked | |||

| Grain collecting type | Manual grain collecting | |||

Technical parameters are subject to change without prior notice.

● Agile Mobility

● Small Size for Working in Small Fields

● Half Feeding, Keeps Straws

● Feeding Quantity:1.0kg/s (4.4lb/s)

● Production Capacity: 0.08-0.15ha/h

GH110 Half-feeding Combine Rice Harvester

Features and Advantages:

1.Gookma GH110 half feeding combine rice harvester is a national major support project of agricultural machinery.

2.The machine is of low-cut stubble,flexible in field operating,

3.It’s small size, light weight, easy in travel control, flexible in turning. It’s simple in disassembling and convenient for maintenance.

4.It can be operated in both dry fields and paddy fields, suitable for harvesting in plain areas and in hilly areas.

5.It’s of compact structure, threshes in two times. The first threshing integrates threshing and conveying, and the second threshing integrates threshing and sundries removal. The overall threshing effect is good.

6.It’s of Low fuel consumption and high working efficiency.

7.The machine keeps straws for recycling applications.

Application Cases

Gookma small half feeding combine rice harvester is suitable for both family use and for small business purpose, it has been selling well and very popular in both domestic and overseas market, and has been enjoying high reputation among customers.

Production Video

High Quality for China Combine Harvester and Rice Harvester, We follow superior mechanism to process these items that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that permit us to provide unmatched quality of products and solutions for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.