10ton HDD machine Horizontal Directional Drilling

10ton HDD machine Horizontal Directional Drilling,

10TON Horizontal Directional Drilling,

Features and Advantages

Gookma horizontal directional drill is professional Integrated designed with many technical advantages, makes the machine of stable performance and high efficiency.

1.Equips with Cummins engine

Equips with Cummins engine, strong power, low fuel consumption, stable and durable.

2. Rack and pinion system

Rack and pinion system, humanization design, Easy for operation and maintenance.

3. The machine equips with 9 Eaton motors of same

The machine equips with 9 Eaton motors of same model and same mounting dimensions, 4 for pushing and pulling, 4 for power head rotating and 1 for pipe changing. All motors are interchangeable, avoid wasting time to wait for new motor for replacing in case of damage of any motor.

4. Big torque

Big torque, fast pushing and pulling speed, high working efficiency.

5. Strengthening design of chassis and main arm

Strengthening design of chassis and main arm, working life more than 15 years.

6. Famous branded main components

Famous branded main components, ensure the stability and reliability of the machine.

7. Special anti-heat design

Special anti-heat design, makes the machine free from overheating, it is specially suitable for working under high temperature conditions.

Applications

Gookma rotary drilling rig is widely applied in many holing construction projects, such as highway, railway, irrigation, bridge, power supply, communication, municipal, garden, house, water well construction etc., and has been enjoying high reputation among customers.

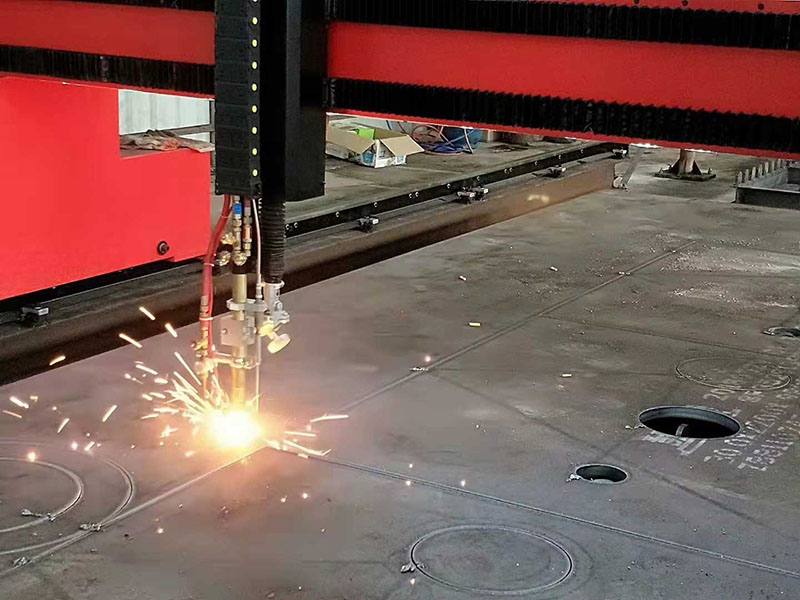

Production Line

Production Video

1.The GD33 horizontal directional drill is of integrated design, with a novel overall looking.

2. The engine is of strong power, low fuel consumption, stable and durable.

3. The hydraulic and electrical parts are of simplified design, make it simple structure, convenient in maintenance and repairing. The machine without any solenoid valve, the operator can repair the machine himself even without experience.

4. Big torque, fast pushing and pulling speed, high working efficiency.

5. Strengthening design of chassis and main arm, working life more than 15 years.

6. Humanization design, simple in operation, easy control.

7.Famous branded main components, ensure stability and reliability of the machine.

8. Special anti-heat design, makes the machine free from overheating, it is specially suitable for working under high temperature conditions.

9. Compact design, small size, agile mobility, can be shipped in 40’GP container.

| Specifications | |

| Name | Horizontal Directional Drill |

| Model | GD33 |

| Engine | Cummins 153KW |

| Push and pull drive type | Chain |

| Max pull back force | 330KN |

| Max push and pull speed | 17s |

| Max torque | 14000N.m |

| Max reaming diameter | 900mm (36in) |

| Standard configuration of reamer | φ250-φ600mm (φ9.85-φ23.64in) |

| Max working distance | 300m (984ft) |

| Drill rod | φ73*3000mm (φ2.88*118.20in) |

| Standard configuration of drill rod | 100 pcs |

| Mud pump displacement | 320L/m |

| Walking drive type | Rubber crawler |

| Walking speed | Double speed |

| Rod changing type | Semi-automatic |

| Anchor | 3 pieces |

| Max grading ability | 20° |

| Overall dimensions (L*W*H) | 6550*2150*2250mm (258.07*84.71*88.65in) |

| Machine weight | 10200kg (22487lb) |

Features and Advantages:

Stable Performance, Excellent Efficiency

1.The machine is of integrated design, with a novel overall looking.

2.Rack and pinion system.

3. The engine is of strong power, low fuel consumption, stable and durable.

4. The hydraulic and electrical parts are of simplified design, make it simple structure, convenient in maintenance and repairing. The machine without any solenoid valve, the operator can repair the machine himself even without experience.

5. The machine equips with 9 Eaton motors of same model and same mounting dimensions, 4 for pushing and pulling, 4 for power head rotating and 1 for pipe changing. All motors are interchangeable, avoid wasting time to wait for new motor for replacing in case of damage of any motor.

6. Big torque, fast pushing and pulling speed, high working efficiency.

7. Strengthening design of chassis and main arm, working life more than 15 years.

8. Humanization design, simple in operation, easy control.

9.Famous branded main components, ensure stability and reliability of the machine.

10. Special anti-heat design, makes the machine free from overheating, it is specially suitable for working under high temperature conditions.

11. Compact design, small size, agile mobility, can be shipped in 40’GP container.

| Specifications | |

| Name | Horizontal Directional Drill |

| Model | GD39 |

| Engine | Cummins 153KW |

| Push and pull drive type | Rack and pinion |

| Max pull back force | 390KN |

| Max push and pull speed | 10s |

| Max torque | 16500N.m |

| Max reaming diameter | 1100mm (43.34in) |

| Standard configuration of reamer | φ300-φ900mm (φ11.82-φ35.46in) |

| Max working distance | 400m (1312ft) |

| Drill rod | φ83*3000mm ( φ3.27*118.2in) |

| Standard configuration of drill rod | 100 pcs |

| Mud pump displacement | 450L/m |

| Walking drive type | Steel lock rubber block crawler self-propelling |

| Walking speed | Double speed |

| Rod changing type | Semi-automatic |

| Anchor | 3 pieces |

| Max grading ability | 20° |

| Overall dimensions (L*W**H) | 6800*2250**2350mm (267.92*88.65*92.59in) |

| Machine weight | 10800kg (23810lb) |